Large-acceptance dipole magnet GLAD

Responsible: GSI and CEA Saclay.

Contact persons: Haik Simon (magnet) and Thomas Hackler (kryogenic system)

General Information

For the variety of experiments to be performed within the R3B project, a zero-degree superconducting dipole magnet has been designed and constructed. The main parameters of the spectrometer are: (i) A large vertical gap providing an angular acceptance of ±80 mrad for neutrons; (ii) A maximum bending angle of 40°, ensuring an acceptance close to 100% even for experiments with very different magnetic rigidities of the beam and the fragments; (iii) A high field integral of about 5 Tm, which allows a bending angle of 18° for a 15 Tm beam (e.g. 1 GeV/nucleon 132Sn or 500 MeV/nucleon 8He) or 14° for 20 Tm beams, the maximum rigidity provided by the Super-FRS. A momentum resolution Δp/p of around 10-3 can be achieved by tracking the particles with high resolution (see here). The design includes four superconducting coils which are tilted to match the required acceptance angle for the particles of interest. The side coils are optimized to reduce the fringe field, and guarantee a low magnetic field in the target region, where detectors have to be placed.

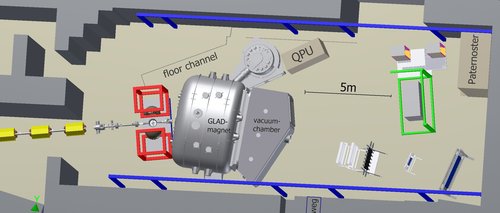

The GSI cite preparation and installation of the GLAD magnet and Helium liquifier plant has been done in common work with FAIR@GSI cryogenic project team, GSI cryogenic group, GSI electric power group and GSI magnet group. The magnet has been has been delivered in November 2015 to GSI. In February 2016 together with its large vacuum chamber the magnet has been moved into Cave C, where it will be used in experiments until the R3B experimental hall is built at the FAIR. The magnet has been commissioned with relativistic beams during the Phase-0 experiments.

GLAD Status

August 2017

The GLAD magnet, presently situated in Cave C, is undergoing the site acceptance test (SAT). After some debugging of the control system, the magnet cooling is behaving as expected from simulations. The magnet is cooled down to liquid-He temperature.

February 2016

- On February 11 the large-acceptance dipole magnet GLAD has been moved to Cave C. Here, it will be used in different secondary-beams experiments until the R3B Cave at FAIR is built. Four days late, also the vacuum chamber has been moved into the Cave C. More photos can be found here.

November 2015

- GSI press release and FAIR press release from November 5th about the arrival of the GLAD magnet at GSI.

- On November 4th the GLAD magnet has arrived to GSI. More infos and photos will follow.

September 2015

- Factory acceptance test for the GLAD magnet has been performed and approved on September 23rd.

April 2015

- On April 24 FAIR has approved the GLAD Technical Design Report.

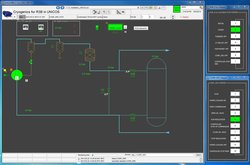

After optimizations of the compressor control system the R3B Kryo team started in the middle of 2014 with the integration of the expansions turbines and the required extension of the UNICOS control system. Before the real start of the coldown of the coldbox with rotating turbines, several simulations had to be done in order to test the control system. In the first step, the control system was tested with fixed values, and in the second step the turbines were simulated with frequency generators. After these successful simulations the turbines were physically integrated in the coldbox to start testing under real conditions at the beginning of December. On 12.12.2014 the R3B coldbox produced the first liquid Helium after over 12 years of downtime. The 18 l vessel inside the coldbox was filled completely. For January 2015 power measurements of the plant are planned.

- The compressor of the R3B cryo plant passed successfully the first overnight run with the new UNICOS control system. The high and low pressures were regulated constantly, and the coldbox without turbines was also integrated in the system. Almost all pressure and temperature sensors can now be read out with UNICOS. Different flow directions through the coldbox were realized by manually driving valves with UNICOS. The modification of the cooling water system in order to reduce the noise inside the target hall was also successfully tested. For the bypass valve two additional small valves for the starting and stopping phase of the compressor were installed and tested successfully as well.

March 2014

- Long term compressor test over three days has been successfully passed. During this test the coldbox was connected the first time after over ten years to a compressor system and a continuous Helium flow was generated through the coldbox.

January 2014

- On January 14, the compressor, an important part of the GLAD magnet cryoplant, has been successfuly put in operation.

December 2013

- Test of the cold mass and coils has been successfully performed. Nominal current of 3584 A has been reached on December 5.

May 2013

- On May 22, 2013 further step in building up the GLAD magnet cryoplant (upgraded TCF 50 Helium liquifier) has been achieved - the compressor building has arrived to the GSI cite (see figure below). The compressor is installed outside the target hall on the west side inside a 6 m container, which is equipped with a special noise insulation. It is a water-cooled rotary srew compressor with 1:1 drive, with no power transmission losses and reduced maintenance costs. It provides a helium mass flow of 61.3 g/s. The compressor dimensions are 2650 x 2180 x 2120 mm3 and weight of 5.4 t, its rated motor power amounts to 200 kW and working pressure is 13.5 bar.

December 2012

- On December 13, 2012 a helium buffer tank needed for the cryostat of the large-acceptance GLAD magnet has been arrived at GSI, see figure below. Its volume amounts to 30 000 l, and gaseous helium will be held inside at an preassure of 13.5 bar. Gaseous helium stored in the buffer will be sent to the helium liquifier where it will be liquified and cooled down to ~4.5 K and then used for the indirect cooling of the cold mass of the GLAD magnet with a two-phase helium thermosiphon.

GLAD Literature

- "Cryogenic Test of the R3B-GLAD Magnetand Status of its Cryostat Production", C. Mayri et al, GSI Scientific Report 2012, PHN-ENNA-EXP-59

- "Status of the R3B GLAD Magnet Cryosystem", C. Betz et al, GSI Scientific Report 2012, PHN-ENNA-EXP-58

- "R3B-Glad Magnet R&D Tests Program: Thermosiphon Loop With Horizontal Section, Superconducting Cable Joints at 3600 A, and

Reduced Scale “Coil in its Casing” Mock-Up"

B. Gastineau et al,

IEEE Trans. Appl. Superconduct., vol. 22, No 3, pp 9001004, June 2012

DOI: 10.1109/TASC.2011.2181471 - "R3B-Glad Magnet Cold Mass Manufacture: Coils and Casings Fabrication and Integration"

G. Disset et al,

IEEE Trans. Appl. Superconduct., vol. 22, No 3, p. 4500804, June 2012

DOI: 10.1109/TASC.2011.2180288 - "Thermo-Mechanical Measurements on Impregnated Cu-NbTi Cable Stacks and on a

Coil Mock-Up of the R3B-GLAD Magnet"

C. Mayri et al,

IEEE Trans. Appl. Superconduct., vol. 20, No 3, pp 1985-1988, June 2010

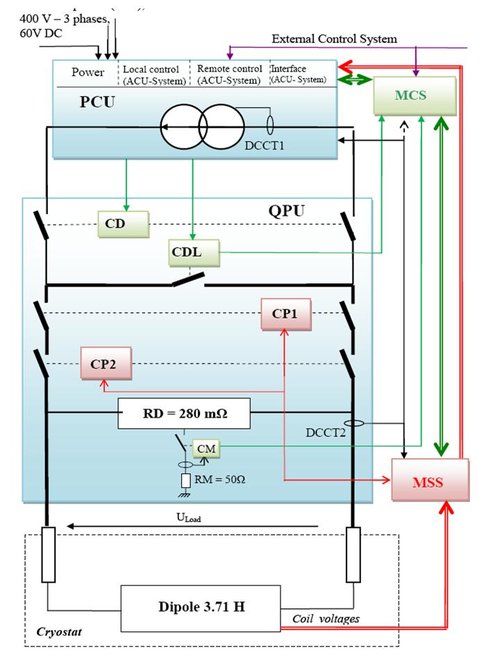

DOI: 10.1109/TASC.2010.2041336 - "The R3B-GLAD Quench Protection System"

Ph. Fazilleau et al,

IEEE Trans. Appl. Superconduct., vol. 20, No 3, pp 2074- 2077, June 2010

DOI: 10.1109/TASC.2010.2043516 - "Temperature Distribution During the Cooling Down of the R3B Magnet Cold Mass"

C. Pes et al,

IEEE Trans. Appl. Superconduct., vol. 20, No. 3, pp 1908-1911 , June 2010

DOI: 10.1109/TASC.2010.2044650 - "Progress in Design and Construction of the R3B-GLAD Large Acceptance Superconducting

Dipole Spectrometer for GSI-FAIR"

B. Gastineau et al,

IEEE Trans. Appl. Superconduct., vol. 20, No 3, pp 328-331, June 2010

DOI: 10.1109/TASC.2010.2040169 - "Progress in the design & construction of the R3B-GLAD superconducting magnet", B. Gastineau et al, GSI Scientific report 2009, FAIR-EXPERIMENTS-17, p. 18.

- "Design Status of the R3B-GLAD Magnet: Large Acceptance Superconducting Dipole With Active

Shielding, Graded Coils, Large Forces and Indirect Cooling by Thermosiphon"

B. Gastineau et al,

IEEE Trans. Appl. Superconduct., vol. 18 No 2, pp 407-410, June 2008

DOI: 10.1109/TASC.2008.922529 - "Mechanical Behavior of the Cold Mass Assembly of the R3B-GLAD Magnet"

Z. Sun et al,

IEEE Trans. Appl. Superconduct., vol. 18, No 2, pp 375-378, June 2008

DOI: 10.1109/TASC.2008.921337 - "Comparison Between Active and Passive Shielding Designs for a Large Acceptance Superconducting Dipole Magnet"

B. Gastineau et al,

IEEE Trans. Appl. Superconduct., vol. 16, no. 2, pp. 485-488, June 2006

DOI: 10.1109/TASC.2006.871328 - "Design Study of the Superconducting Magnet for a Large Acceptance Spectrometer"

A. Dael et al,

IEEE Trans. Appl. Superconduct., vol. 12, No. 1, p. 353-357, March 2002

DOI: 10.1109/TASC.2002.1018418