The electrostatic injection septum is used to inject the beam of the linear accelerator UNILAC into the ring accelerator SIS18. This is a so-called "multiturn injection", meaning, that the ring is not filled in one but in many cycles.

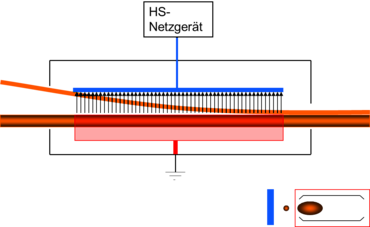

This is possible by special ion-optical settings of the SIS18. Through the septum, the already orbiting beam flies through a hollow anode construction, while the incoming 'injected' beam is aligned parallel to the orbiting beam by an electric field. The picture shows the two beam parts from above and in direction of the beam (lower right corner of the picture).

The anode construction consists of many closely arranged, spring-loaded wires. A single wire has a diameter of only 0.1 mm. The cathode is made of anodized aluminum.

Our injection septum is supplied with voltage from outside the ring tunnel

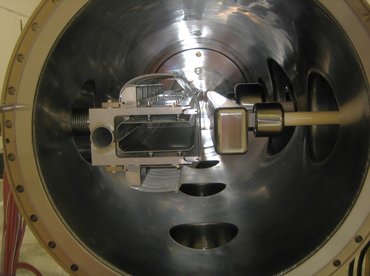

In the case of a flashover in the 1.5 m long electrode system, the capacity of the long supply line would lead to a high discharge current.

In order to prevent damage to the electrical system, a high-voltage series resistor is installed near the septum which limits the current.

This resistor is shown in the picture. The unit is powered by a 300kV power supply using voltages up to 180kV.

At the electrode spacing of 3 cm, a field of up to 60 kV / cm is used to deflect the injected beam.

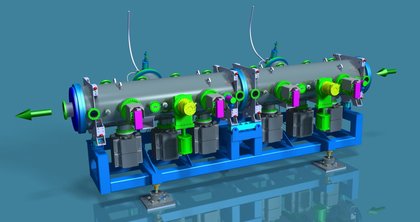

Similar to the injection septum, there is also a septum for the slow extraction of the beam to the experiments. A part of the beam is deflected after the acceleration. Due to the higher kinetic energy, higher fields are required here for the same electrode length. This is achieved by a smaller distance of the electrodes of only 2 cm.

At the maximum voltage of the power supply used there, 80 kV / cm can be used.

Also in the SIS100 there will be an electrostatic extraction septum. Due to the increased bending stiffness of the ion beam and the limits set by the maximum electrical deflection field, a significantly longer design with a length of approximately 5 m must be built for the desired deflection angle.